Bronze Valves

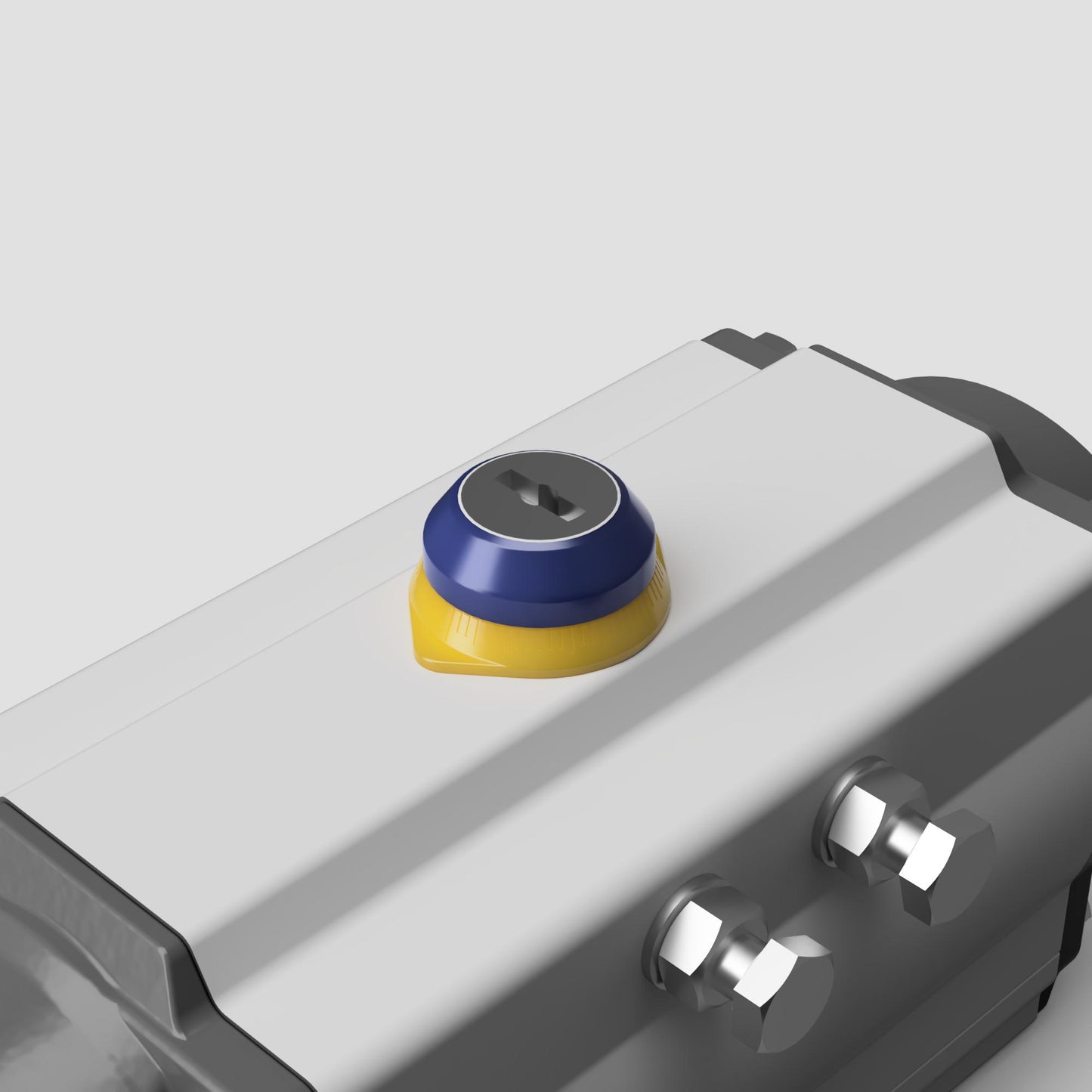

Air Torque Pneumatic Actuator

Air Torque Pneumatic Actuator

Couldn't load pickup availability

The Air Torque Pneumatic Actuator is a high-performance rack and pinion actuator engineered for precise 90° rotary motion in automated valve control. Manufactured with an anodised aluminium body, it delivers excellent resistance to corrosion, wear, and harsh environments—making it ideal for use in water, chemical, process, and general industrial applications.

This actuator is designed to meet SIL 3 (Safety Integrity Level 3) compliance, ensuring dependable performance in safety-critical systems. With a compact and robust design, the actuator provides smooth, consistent torque output and long service life. Whether operating as double acting or spring return, Air Torque actuators are trusted for their durability and reliability in both safe and hazardous environments.

Key Features:

- Rack & Pinion Design: Delivers balanced torque and precise 90° rotation for reliable valve control

- Anodised Aluminium Body: Corrosion-resistant, lightweight, and built for long-term use in demanding environments

- SIL 3 Certified: Suitable for high-integrity safety systems, meeting international standards

- 90° Operation: Ideal for quarter-turn valves such as ball, butterfly, and plug valves

- Compact & Modular: Easy to mount with standard ISO interfaces (ISO 5211 and Namur)

- Spring Return or Double Acting: Configurable actuation for fail-safe or continuous control applications

- Low Maintenance: Engineered for high cycle life with minimal servicing required

Technical Specifications:

- Actuation Type: Pneumatic – Rack and Pinion

- Rotation: 90 Degrees

- Body Material: Anodised Aluminium

- Torque Output: Varies by model (consult sizing chart)

- Mounting Interface: ISO 5211

- Top Mount Interface: Namur standard for solenoid valves

- Operating Pressure: Typically 2.5 to 8 bar

- Temperature Range: -20°C to +80°C (standard), optional versions available for wider ranges

- Certification: SIL 3, ATEX versions available

Why choose us?

-

Built to Last

Our bronze valves are engineered for long-term durability, corrosion resistance, and consistent performance across demanding applications.

-

Expert Support

We combine technical knowledge with real-world experience to help you find the right valve solution for your system — fast.

-

Fast Turnaround

With efficient stock handling and responsive service, we keep your projects moving without unnecessary delays.

FAQs

What are bronze valves used for?

Bronze valves are commonly used for isolating, regulating, and directing the flow of water, steam, air, and non-aggressive fluids in industrial, marine, and commercial systems. Their corrosion resistance makes them ideal for saltwater and outdoor applications.

Are bronze valves suitable for potable water?

Yes, bronze valves are often used in potable water systems, especially when made from lead-free or WRAS-approved bronze alloys. Always verify material compliance with local drinking water standards.

What is the difference between bronze and brass valves?

Bronze is an alloy of copper and tin, offering better corrosion and wear resistance than brass, which is typically made of copper and zinc. Bronze valves are generally more durable and preferred for marine and industrial applications.

Can bronze valves handle high temperatures and pressures?

Yes, most bronze valves are rated for moderate to high temperatures and pressures. Many models can handle up to PN25 or 600 psi, and temperatures ranging from -10°C to 150°C, depending on design and sealing materials.

Do bronze valves require regular maintenance?

Bronze valves are low-maintenance, but like any mechanical component, periodic inspection and cleaning (especially strainers and check valves) are recommended to ensure long-term performance and safety.