Bronze Valves

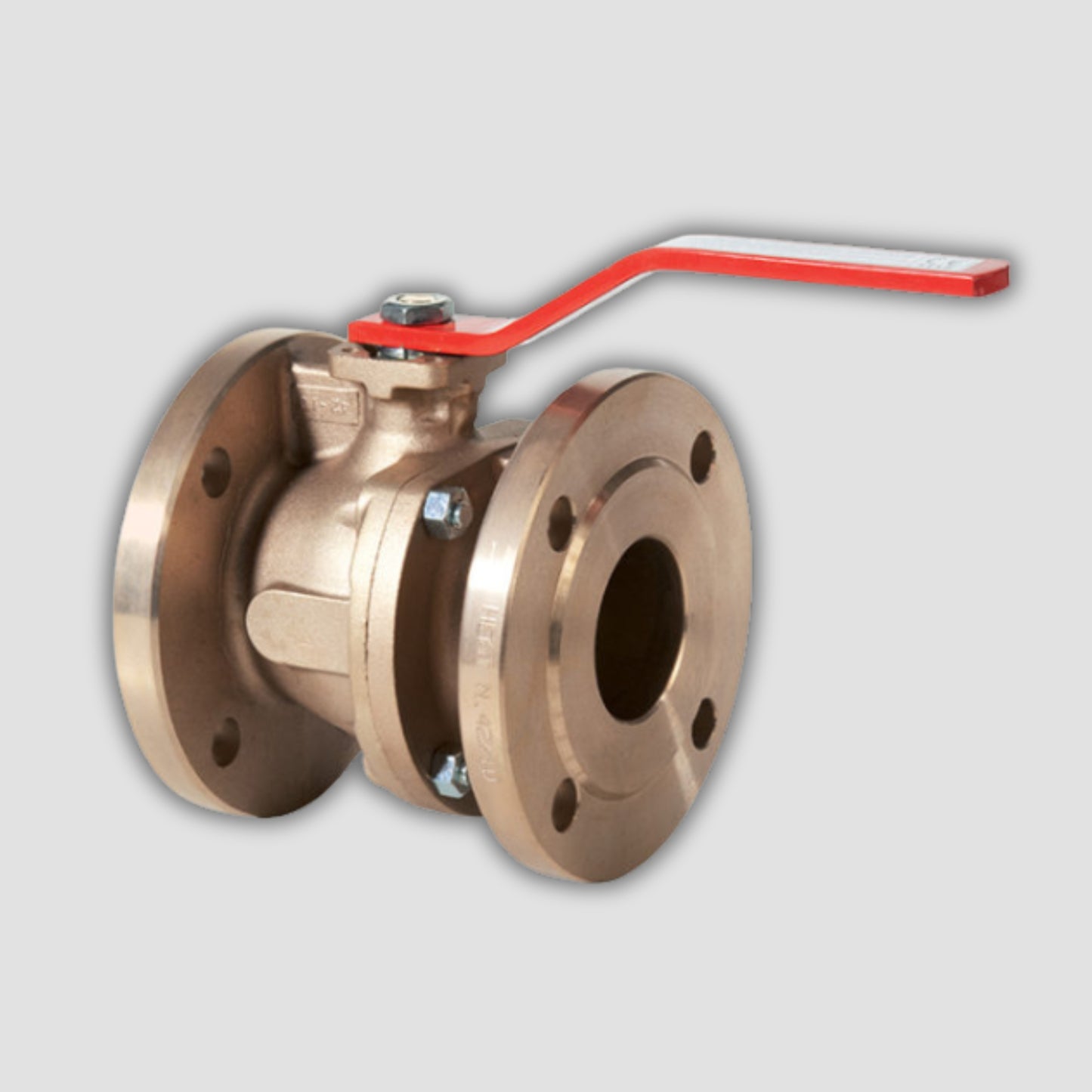

Premium Bronze Ball Valve – Flanged ANSI 150 – ISO 5211 Mount

Premium Bronze Ball Valve – Flanged ANSI 150 – ISO 5211 Mount

Couldn't load pickup availability

The Premium Bronze Ball Valve – Flanged ANSI 150 is built to deliver uncompromising reliability, corrosion resistance, and ease of operation in demanding fluid control environments. Constructed with an ASTM B62 bronze body and 316 stainless steel ball and stem, this valve ensures long-term performance in water, oil, steam, and light chemical systems.

Featuring ANSI 150 flanged ends with ANSI face-to-face dimensions, the valve is fully ISO 5211 compliant for direct mounting of actuators—eliminating the need for additional brackets or couplings. Its full bore design minimises pressure drop, while PTFE seats and Viton stem O-rings provide superior sealing and chemical resistance. Lever operated and rated for use from -10°C to 150°C, it’s a premium solution for industrial, marine, and processing systems.

Key Features:

- Flanged ANSI 150 with ANSI face-to-face dimensions

- ISO 5211 pad for direct actuator mounting

- ASTM B62 bronze body with 316 stainless steel ball & stem

- Full bore for optimal flow and minimal pressure loss

- PTFE seats and Viton stem O-rings for enhanced sealing and resistance

- Lever operated, rated for -10°C to 150°C

- Suitable for water, oil, steam, and general industrial use

Why choose us?

-

Built to Last

Our bronze valves are engineered for long-term durability, corrosion resistance, and consistent performance across demanding applications.

-

Expert Support

We combine technical knowledge with real-world experience to help you find the right valve solution for your system — fast.

-

Fast Turnaround

With efficient stock handling and responsive service, we keep your projects moving without unnecessary delays.

FAQs

What are bronze valves used for?

Bronze valves are commonly used for isolating, regulating, and directing the flow of water, steam, air, and non-aggressive fluids in industrial, marine, and commercial systems. Their corrosion resistance makes them ideal for saltwater and outdoor applications.

Are bronze valves suitable for potable water?

Yes, bronze valves are often used in potable water systems, especially when made from lead-free or WRAS-approved bronze alloys. Always verify material compliance with local drinking water standards.

What is the difference between bronze and brass valves?

Bronze is an alloy of copper and tin, offering better corrosion and wear resistance than brass, which is typically made of copper and zinc. Bronze valves are generally more durable and preferred for marine and industrial applications.

Can bronze valves handle high temperatures and pressures?

Yes, most bronze valves are rated for moderate to high temperatures and pressures. Many models can handle up to PN25 or 600 psi, and temperatures ranging from -10°C to 150°C, depending on design and sealing materials.

Do bronze valves require regular maintenance?

Bronze valves are low-maintenance, but like any mechanical component, periodic inspection and cleaning (especially strainers and check valves) are recommended to ensure long-term performance and safety.